Computer controlled cutting

[°ロ°]

[°ロ°]

Laser cutting is a subtractive manufacturing process. It basically uses a Laser to cut through a sheet material. The high intensity of the laser beam causes the material to be vaporised.

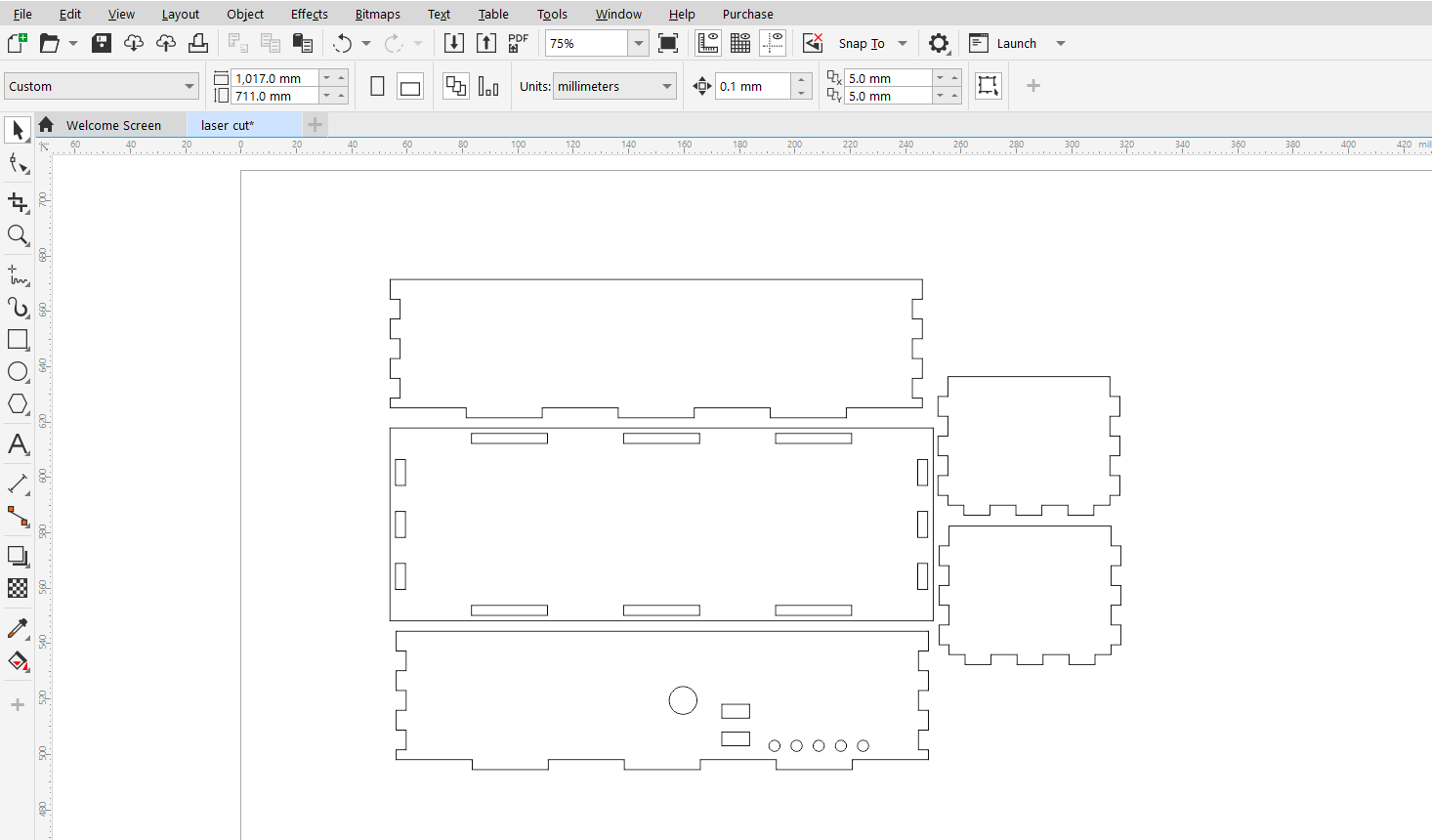

I will be using the laser cutter to cut out my laser cut box design.As I will be using wood material, I set the thickness parameter to 3.5mm.

.png)

I modified the box parameters and added some cut features to house electronics. First I need to convert the file into a DXF document.

I first select the object I want and Create a new sketch. I then click on the surface I want until it turns blue.

.png)

I renamed the sketch as "Base.dxf" to differentiate it from the other sketches.

.png)

I then right click on the sketch and select "save as dxf".

.png)

If there are parts with similar profiles, you can just convert 1 part.

Once converting the parts, I import the files into corelDraw to check and finalise before sending it to the laser cutter.

Profiles should be arranged to minimise material wastage.

I then send the file to laser cut. Here is a time lapse of the process:

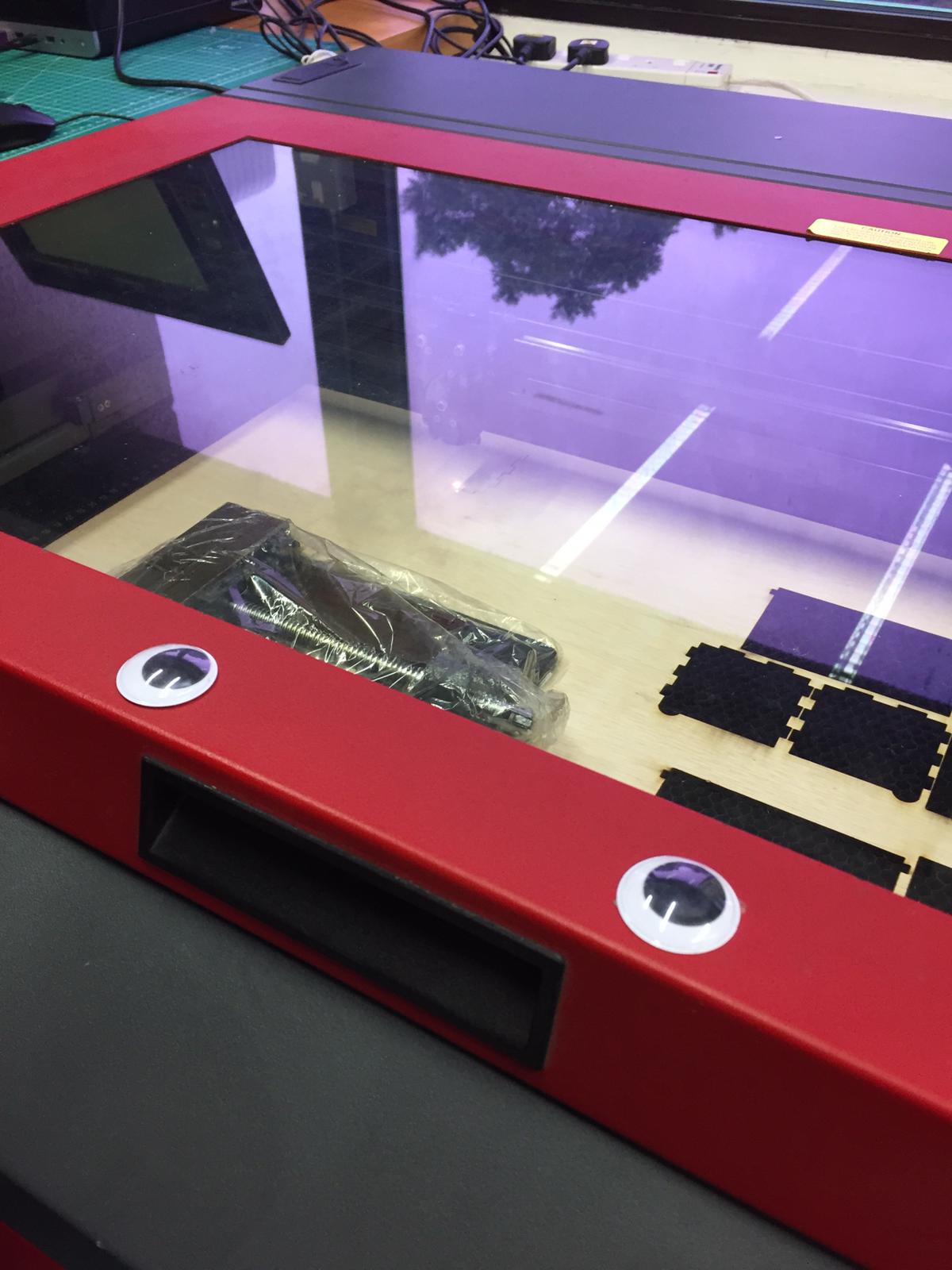

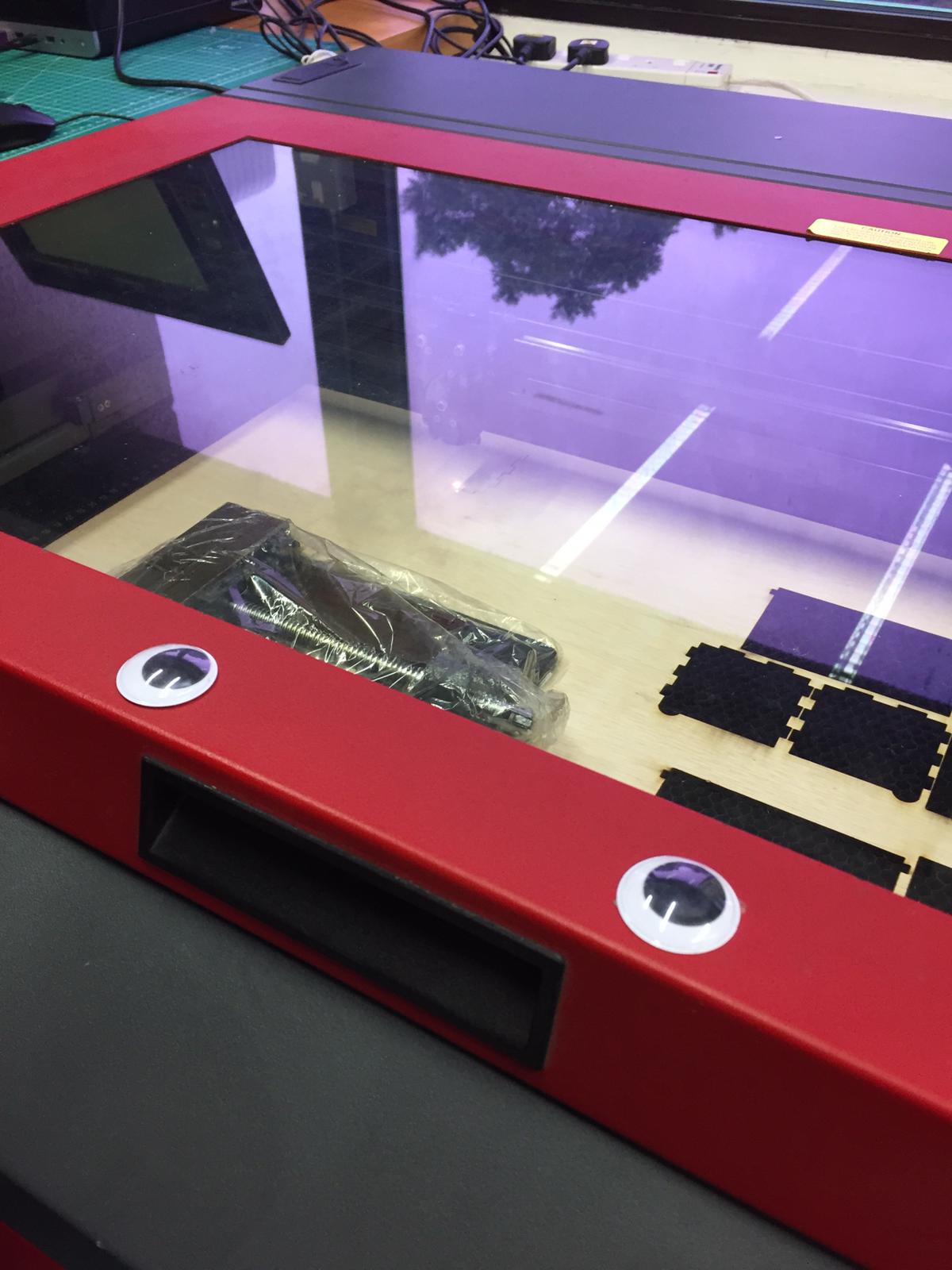

Completed box and assemble

.jpeg)

.jpeg)